We Are Looking For Products You Search

Carraro has published repair recommendations for axles and transmissions on its official website. In the content of this manual; There are subheadings such as shaft oil seals, o-ring, setting shims, bearings, spring pins, cleaning and control of spare parts. We highly recommend that you read the following articles before starting the assembly process.

You may take the below tips in to account for shafts oil seals assembly.

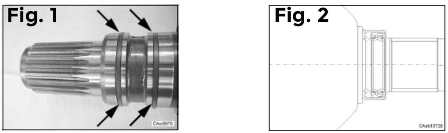

clean the shaft properly first and pay attention that the parts in contact with the seals are in good condition (Fig.1);

it is important not to damage the seals during the assembly;

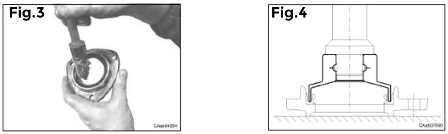

the lip should be fitted towards the oil side when assembled. (Fig.2). It is possible to have some cases that would require a different assembly, therefore please control the existing orientation of the ring before disassembly.

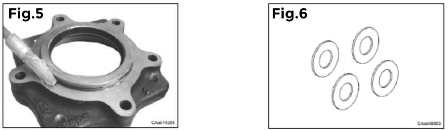

lubricate seals lip (Fig.3); use a suitable device to assemble the seals (Fig.4).

P.S: Highly recommended not to use a hammer directly on the seals.

Lubricate the O-rings before placing them in their seats and not roll the O-rings during the assembly of the shaft (Fig.5).

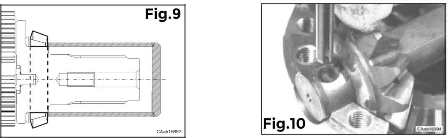

Proper setting shims and the correct combination should be used to get the required dimensions (Fig.6).

It is recommended to follow the below instructions for bearings assembly. Prior to reassembly of the bearings, control them, clean and lubricate. You should warm them up at 80-90 °C (Fig.7) before the assembly to the shaft and cool them before placing them in their seats;

Pay attention to using correct and proper tools to disassemble and assemble the bearings (Fig.8 – Extractor, Fig.9 -Driver).

Please see the instructions below for the assembly.

Before the assembly of the spring pins process starts, be careful about the point that the notch should be oriented towards the stressing force (Fig.10); and spiral spring pins are not required to have an orientation.

Cleaning the axle/transmission:

Wash all moving parts properly with diesel fuel or kerosene gasoline.

Watery alkaline solutions are strictly prohibited.

You should not wash with steam or hot water, due to the fact that it would be not easy to get rid of the surface humidity.

Proper drying is required to all details with an air jet or rag to avoid scratching the surface.

Once the cleaning is done, all the surfaces should be lubricated to avoid oxidation

Control all the splines and make sure that they are not damaged; if there is any damaged part, replace it with genuine spare parts.

Prior to final assembly, the seals (both static and dynamic) on rotating shafts and/or closing cover must be replaced.

Check and control all the bearings and external rings which still can be placed in assembled positions on their seats or other parts with bearing function;

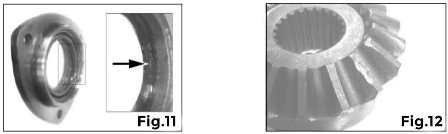

It is too important to replace all parts which seem to have a presence of wear or damage (Fig.11);

Make sure that all gears seem alright and no sign to have damage, chipping, or excessive wear of teeth(Fig.12).

Be careful hammering special tools or flanges to avoid compromising the integrity or functionality of the tools and/or the components on which you are working on.